Wedged Wire Screen

The support profile can be constructed from a variety of materials, including triangular wire, wedge wire, round bars, or rectangular bars. This flexibility allows for compatibility with different machines and equipment, making them suitable for a wide range of applications.

Wedge wire screen panels are ideal for various industries, including water treatment, food processing, mining, and petrochemical applications. Their adaptable design ensures reliable performance and effective separation in diverse operational environments.

Wedge wire screen panels consist of two key components: the surface profile and the support profile. The surface profile is typically made of triangular wire, designed for efficient filtration and optimal flow.

The support profile can be constructed from a variety of materials, including triangular wire, wedge wire, round bars, or rectangular bars. This flexibility allows for compatibility with different machines and equipment, making them suitable for a wide range of applications.

Wedge wire screen panels are ideal for various industries, including water treatment, food processing, mining, and petrochemical applications. Their adaptable design ensures reliable performance and effective separation in diverse operational environments.

With their combination of robust construction and customizable profiles, wedge wire screen panels provide an effective solution for filtration and separation needs across multiple sectors.

Advantages of Wedge Wire Screen Panels

- Flat Surface: The flat design facilitates even distribution of material and enhances the effectiveness of filtration.

- Excellent Filtration Performance: The precision of the wedge wire design ensures optimal separation of solids from liquids, providing superior filtering capabilities.

- Accurate Spacing: The consistent distance between supporting profiles contributes to the reliability and efficiency of the screening process.

- Welded Production Process: The robust welded construction results in a solid and durable structure that can withstand harsh operating conditions.

- Good Mechanical Properties: Wedge wire screens are designed to handle mechanical stress, providing long-lasting performance.

- High Strength and Load Capacity: These panels are engineered to bear heavy loads while maintaining structural integrity.

- Corrosion and Rust Resistance:Constructed from stainless steel, wedge wire screens resist corrosion and rust, ensuring longevity.

- Temperature Resistance: They perform well under varying temperatures, making them suitable for a wide range of environments.

- Chemical Stability: The materials used are stable and resistant to chemical reactions, ensuring reliability in diverse applications.

Applications

Wedge wire screen panels are versatile and find use in numerous applications, primarily in sieving and filtration. They can also serve decorative purposes in various architectural designs. Key application areas include:

- Vibrating Screen Decking: Efficiently separates materials in mining and aggregate industries.

- Surface Water Intake Screens: Protects pumps and equipment from debris in water intake systems.

- Fish Diversion Screen Panels: Safeguards aquatic life while allowing water flow in fisheries and water management systems.

- Hatchery Screens: Ensures effective filtration in aquaculture settings.

- Grain Drying Screens: Facilitates airflow and moisture control in grain processing.

- Malt Kin or Germination Floors: Provides a suitable environment for germination processes in brewing.

- Decorative Materials: Enhances aesthetic appeal in architectural applications.

With their numerous advantages and broad range of applications, wedge wire screen panels are an essential solution for various industrial needs.

Hot sale products:

0.1mm slot flat wedge wire screen

Brief description

0.1mm slot flat wedge wire screen is manufactured by wrapping and welding stainless steel V-shaped profile wire cylindrically around support rods,then be made to panel screen through cutting and edge welding. Each profile wire and support rod is contacted by resistance welding. This screen is with features of firm in structure,good mechanical properties, high strength, rigidity and load capacity. For the section of profile wire is V shaped,the screen slot is narrow in the above and wide in the below,and thus be easy to leakage,wear and corrosion resistance, avoiding clogging and ensure smooth filtration. 0.1mm slot flat wedge wire screen is widely used for feed screening, stool separation,gratings and stairs,facade wall project and so on.

Material

Stainless Steel:304 304L 316 316L 321

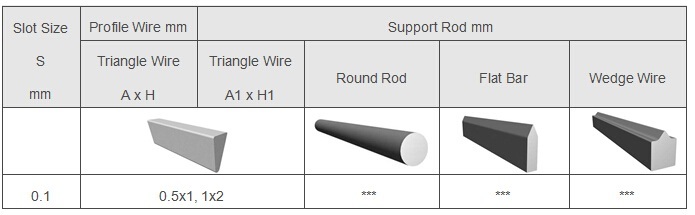

0.1mm flat wedge wire screen technical parameter

common size of flat wedge wire screen: 500x500mm-3000x3000mm,500x1000mm-2000x3000mm

Note

Slot Size (S): The distance between each profile wire.

Profile Wire: Triangle wire is common type.

Support Rod: Triangle wire is common type.

Support Rod Distance (P): The distance between each support rod.

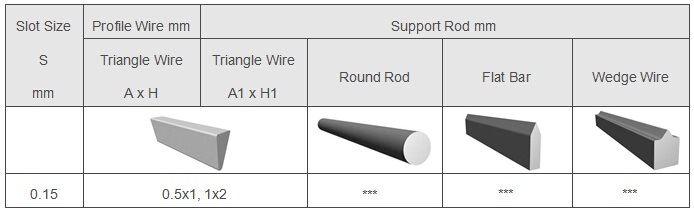

0.15mm flat wedge wire screen technical parameter

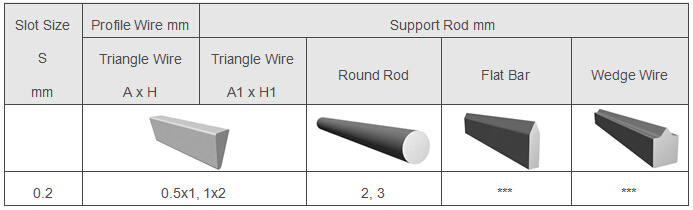

0.2mm flat wedge wire screen technical parameter

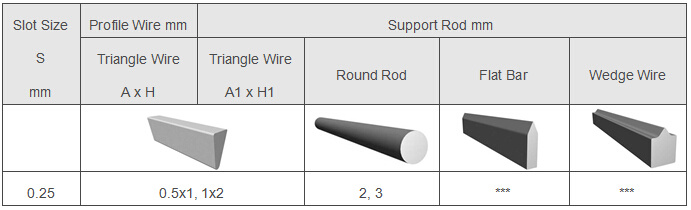

0.25mm flat wedge wire screen technical parameter

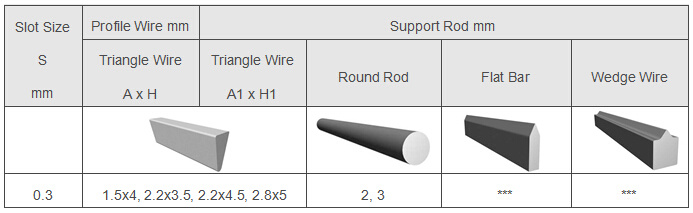

0.3mm flat wedge wire screen technical parameter

Application:

mash tun

filtration tank

liquid and solid separation

beer and food processing.

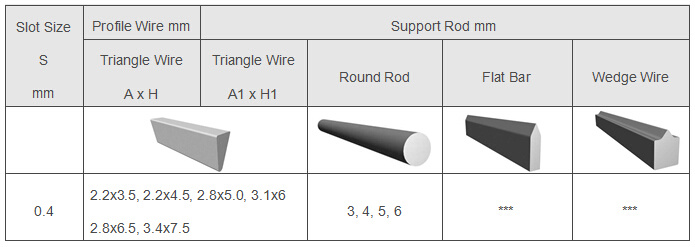

0.4mm flat wedge wire screen technical parameter

Application:

Filtration

food processing

ish division screens.

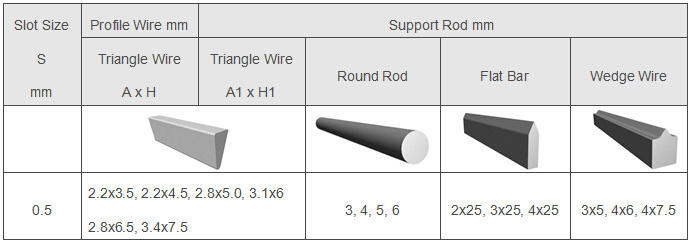

0.5mm flat wedge wire screen technical parameter

Application:

filtration and separation

vibrating screen

food processing

oil refining

food and vegetables processing

waste water separation

waste water treatment

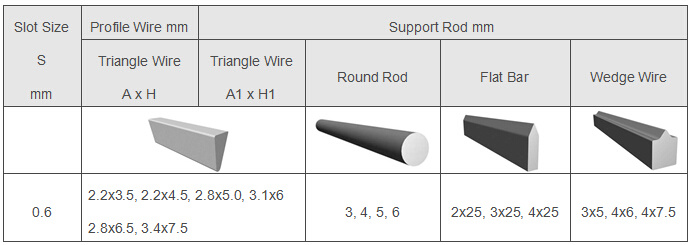

0.6mm flat wedge wire screen technical parameter

Application:

medium separation

food processing

gravel filter

water treatment

environmental protection

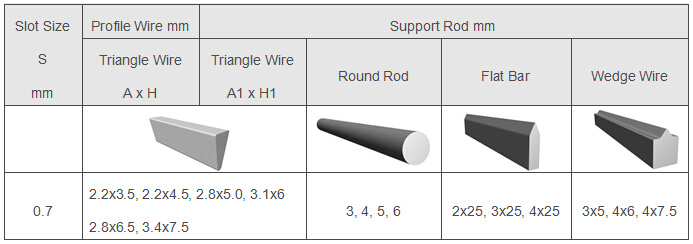

0.7mm flat wedge wire screen technical parameter

Application:

medium separation

food processing

gravel filter

water treatment

environmental protection

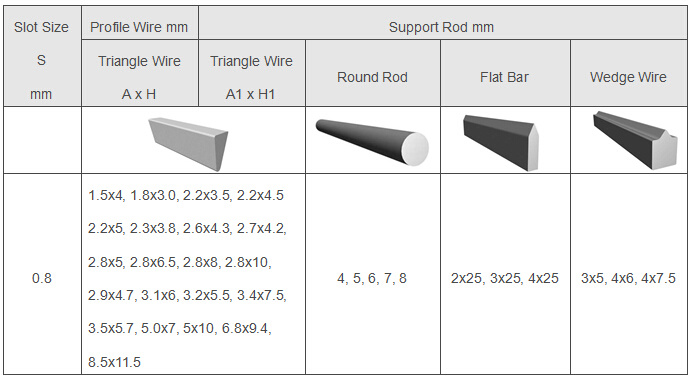

0.8mm flat wedge wire screen technical parameter

Application

medium separation

food processing

gravel filter

water treatment

environmental protection

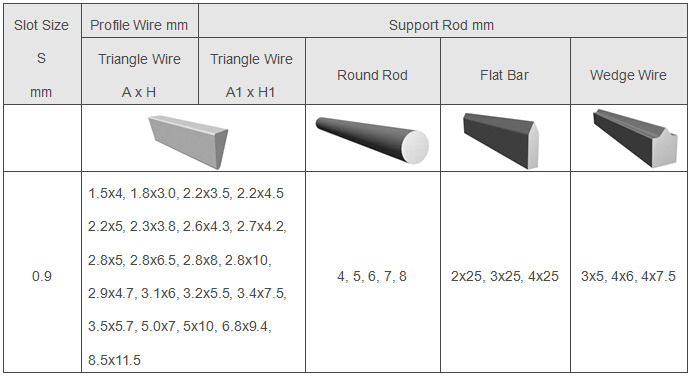

0.9mm flat wedge wire screen technical parameter

Application

medium separation

food processing

gravel filter

water treatment

environmental protection

1mm flat wedge wire screen technical parameter

Application

medium separation

food processing

gravel filter

water treatment

environmental protection

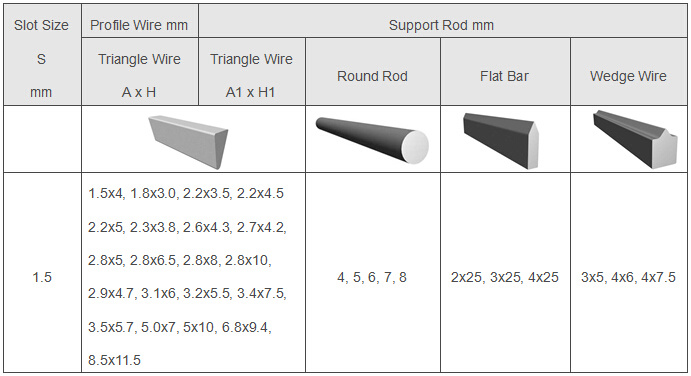

1.5mm flat wedge wire screen technical parameter

Application

medium separation

food processing

gravel filter

water treatment

environmental protection

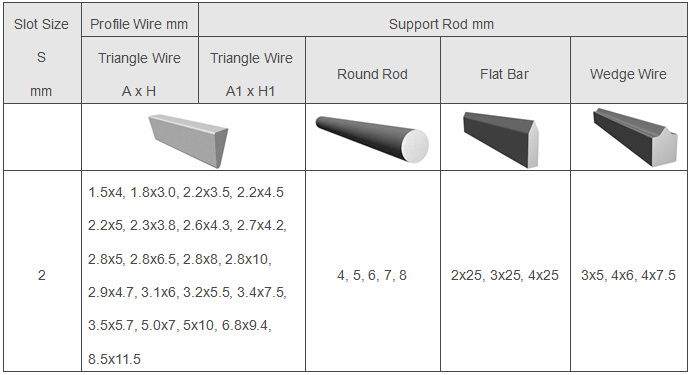

2mm flat wedge wire screen technical parameter

Application

Barbecue

Construction

petroleum chemical industry

dehydrated wastewater treatment for meat

poultry and vegetables processing

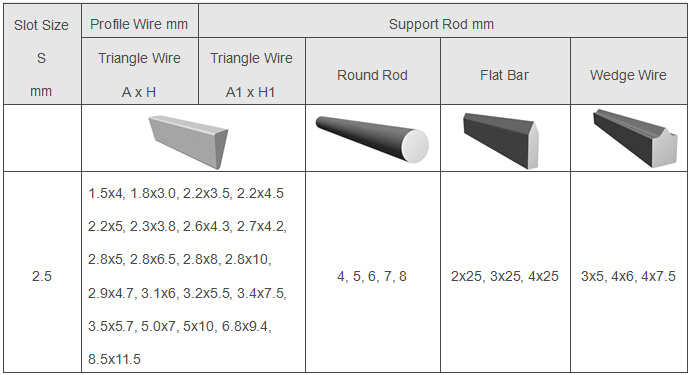

2.5mm flat wedge wire screen technical parameter

Application

Barbecue

Construction

petroleum chemical industry

dehydrated wastewater treatment for meat

poultry and vegetables processing

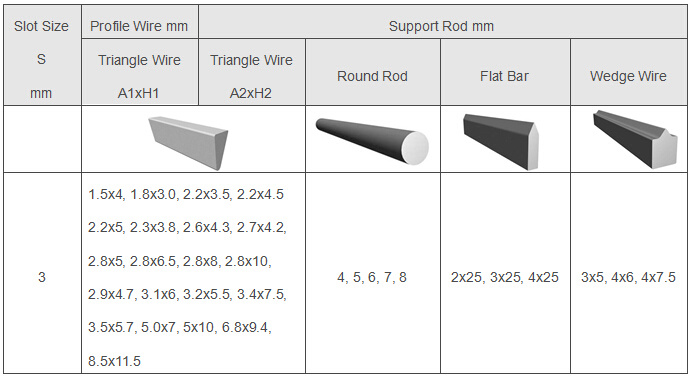

3mm flat wedge wire screen technical parameter

Application

Barbecue

Construction

Petroleum chemical industry

Dehydrated wastewater treatment for meat

poultry and vegetables processing

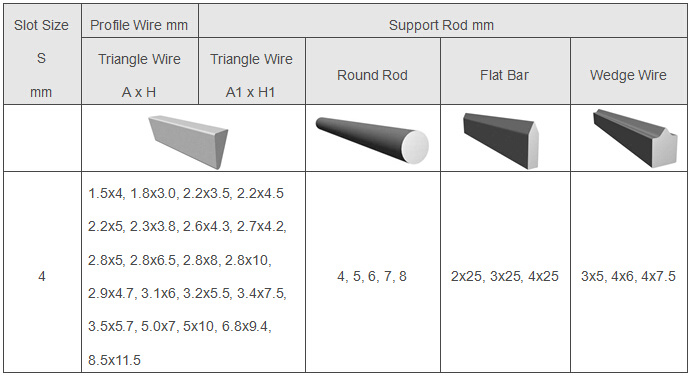

4mm flat wedge wire screen technical parameter

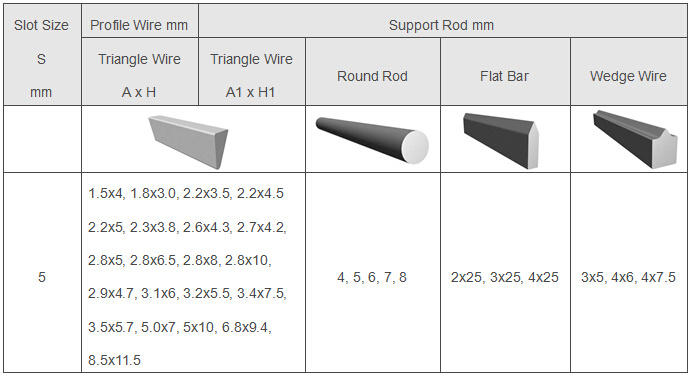

5mm flat wedge wire screen technical parameter

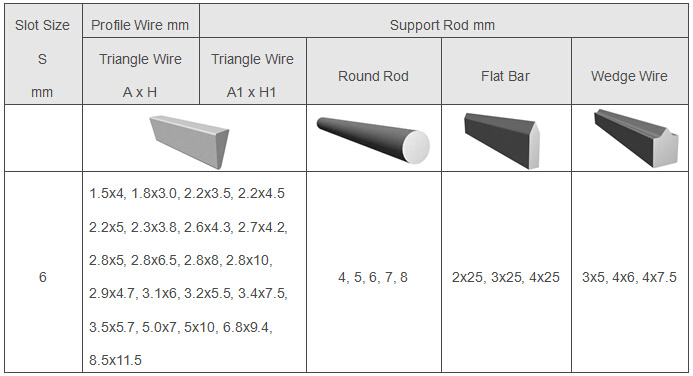

6mm flat wedge wire screen technical parameter

Application

energy exploration

gas processing

mining and minerals processing

food processing

paper making industry.

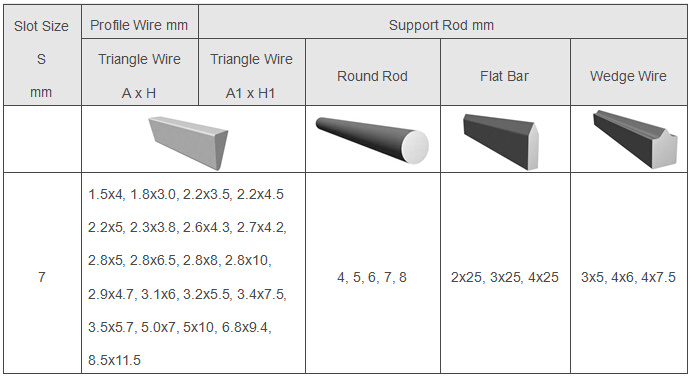

7mm flat wedge wire screen technical parameter

Application

energy exploration

gas processing

mining and minerals processing

food processing

paper making industry.

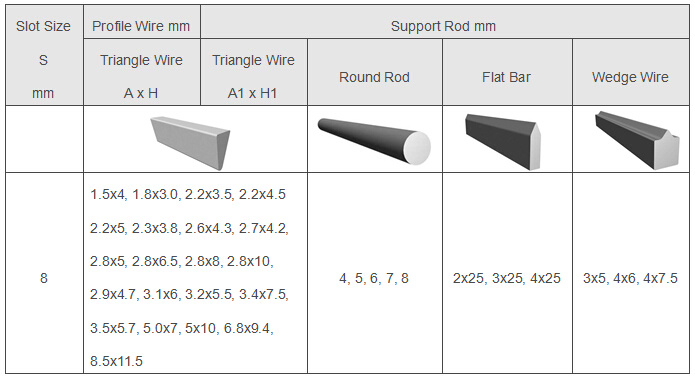

8mm flat wedge wire screen technical parameter

Application

energy exploration

gas processing

mining and minerals processing

food processing

paper making industry.

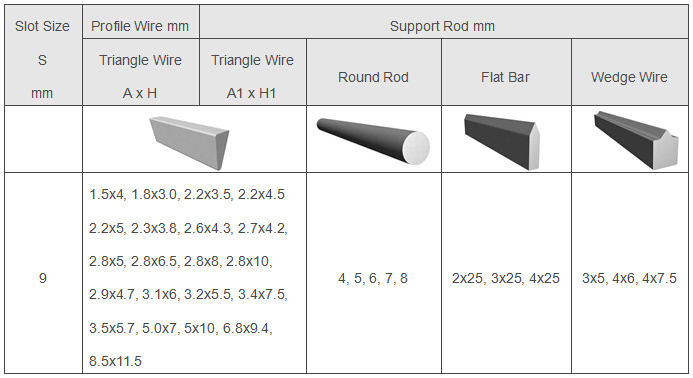

9mm flat wedge wire screen technical parameter

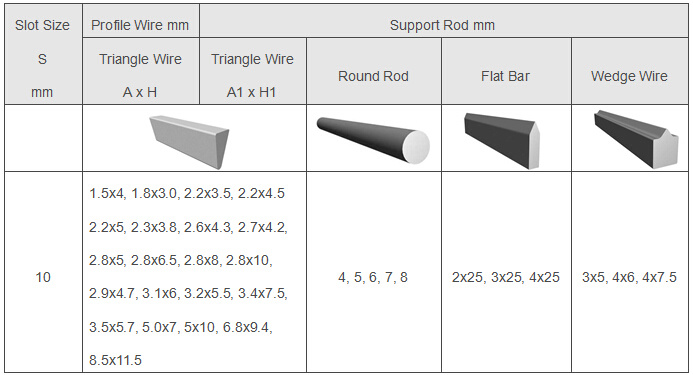

10mm flat wedge wire screen technical parameter

Application

energy exploration

gas processing

mining and minerals processing

food processing

Packing

Flat wedge wire screen should be packed firmly and securely. When packing, flat wedge wire screen appears in panels. They are wrapped with moisture-proof paper or other packing materials inside.The outer package should be wooden pallets or wooden cases.We can also pack according to customer requirements.