Wedge Wire Coanda Screen

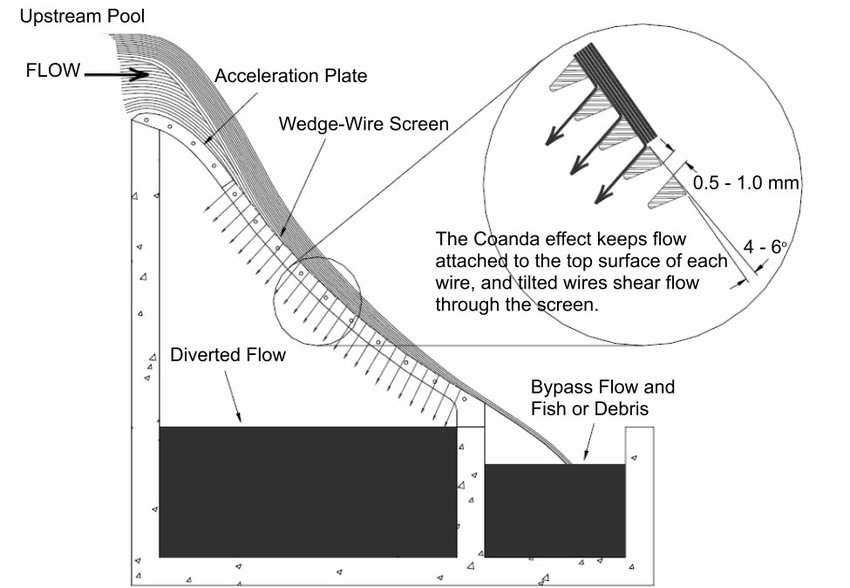

The Coanda effect promotes stable contact with the Johnson screen surface. Place the profile wire within a precise and consistent gap clearance tolerance to screen out debris and particles.

Customized Coanda Screen design 316L Stainless Steel water filtration coanda screen box intake hydropower plant intakes

what is a Coanda screen?

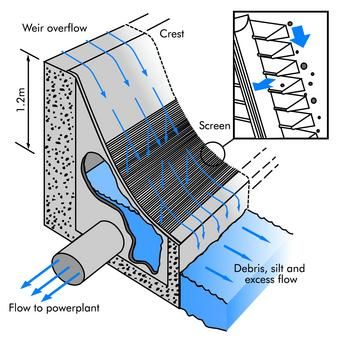

Coanda Hydro Intake Screen combines wedge wire technology and Coanda effects and is widely used in water conservancy projects, power plants, industrial area water, and agricultural irrigation.

The Coanda effect promotes stable contact with the Johnson screen surface. Place the profile wire within a precise and consistent gap clearance tolerance to screen out debris and particles.

We have more than 20 years of experience in Johnson screen product production. At present, we are the largest component manufacturer of the Coanda screen in northern China, providing customized services for more than 50 countries in the world.

Slot team of engineers has simplified this design process by establishing standard profiles, micro hydro packages, and some simple spillway designs to guide your team.

Coanda Screen Specifications for Hydropower Intake – 316L Stainless Steel**

- **Material**: Premium **316L Stainless Steel** for superior corrosion resistance and durability in harsh environments.

- **Slot Size (Aperture)**: Available in **1.0 mm, 1.5 mm**, or customizable from **0.1 mm to 2 mm**, tailored to your specific filtration needs.

- **Profile Wire Tilt Angle**: Standard **5-degree tilt**, adjustable to match project-specific water flow and debris removal requirements.

- **Purpose**: Efficiently removes trash, stones, leaves, and aquatic life from water streams, ensuring clean water flow for hydropower plants, irrigation, and industrial applications.

- **Types**:

- **Single Screens**: For smaller or standard hydropower installations.

- **Multiple Screen Installations**: For larger hydro projects requiring increased capacity.

- **Screens with Integral Sumps**: Designed with sump systems for enhanced water collection and debris handling.

Coanda Screen for Water Intake:

Our **Coanda Screen** maximizes efficiency by utilizing the **Coanda effect**, which improves filtration performance as water velocity increases. The **approach plate** accelerates water flow onto the screen surface, ensuring effective debris removal. A steeper incline and deeper drop improve performance, but our design optimizes for both high-flow scenarios and overall efficiency, balancing incline angles and drop depths to minimize head loss, crucial for power generation and pressure flow systems.

Advantages of Coanda Screen:

1. **Low maintenance costs** due to minimal intervention required.

2. **No moving parts**, reducing wear and the need for repairs.

3. **Self-cleaning ability**, leading to significant savings in maintenance costs.

4. **High flow capacity** thanks to wedge wire technology.

5. **Wear and corrosion resistance**, utilizing our patented surface treatment for longer lifespan.

6. Reliable performance in **low-temperature environments**, unaffected by external conditions.

7. **Fish-friendly design**, ensuring no harm to aquatic life.

Factory and Workmanship:

Our state-of-the-art manufacturing facility adheres to the highest quality standards, producing durable and efficient Coanda screens tailored to meet your water intake requirements.

Application:

hydropower plant intakes

water conservation schemes

irrigation programs