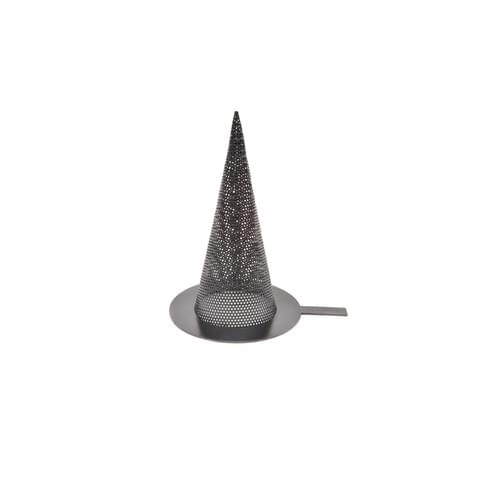

Temporary Cone Strainer

Mesh lined temporary cone strainers retain finer particulate and the mesh is always located on the upstream surface, thus the underlying perforated substrate sully supports the delicate mesh lining. Standard mesh lining sizes are 20, 30, 40, 50, 60, 80, 100, 150 and 200.

Temporary cone strainers, nicknamed witch hat strainers due to their pointy-end design, are the most versatile style for temporary strainers because they can be installed with the narrow end with or against the pipeline flow. The typical installation is orienting the pointy end against the pipeline flow, causing particulate to gradually build-up around the circumference of the pipeline. They are also used to capture particulate with the highest straining ratio possible for a given pipeline size. We can provide temporary cone strainers for 150# and 300# pipelines from 3/4" to 24" in size made of carbon steel, 304LSS or 316L SS. The standard perforation is 1/8", although we can supply with other perforation sizes as well as with mesh lining.

Mesh lined temporary cone strainers retain finer particulate and the mesh is always located on the upstream surface, thus the underlying perforated substrate sully supports the delicate mesh lining. Standard mesh lining sizes are 20, 30, 40, 50, 60, 80, 100, 150 and 200.

The standard open area ratios are 100% or 150%, we can provide proposals for longer elements as required.

Temporary cone strainers, nicknamed witch hat strainers due to their pointy-end design, are the most versatile style for temporary strainers because they can be installed with the narrow end with or against the pipeline flow. The typical installation is orienting the pointy end against the pipeline flow, causing particulate to gradually build-up around the circumference of the pipeline. They are also used to capture particulate with the highest straining ratio possible for a given pipeline size. We can provide temporary cone strainers for 150# and 300# pipelines from 3/4" to 24" in size made of carbon steel, 304LSS or 316L SS. The standard perforation is 1/8", although we can supply with other perforation sizes as well as with mesh lining.

Mesh lined temporary cone strainers retain finer particulate and the mesh is always located on the upstream surface, thus the underlying perforated substrate sully supports the delicate mesh lining. Standard mesh lining sizes are 20, 30, 40, 50, 60, 80, 100, 150 and 200.

The standard open area ratios are 100% or 150%, we can provide proposals for longer elements as required.

In the photo above, the cone is pointing downstream. In this orientation, debris is captured at the pointed portion of the strainer. The photo also shows a velocity profile for fully developed flow. While the flow regimes are different depending on whether or not the flow is laminar or turbulent, the general characteristics stay the same. The flow is lower near the walls of the pipe and the velocity is higher in the center of the pipe. If the cone is pointed with the tip facing downstream, debris will collect in the tip and may rip the cone apart due to heavier strain on the tip.A reason for this orientation would be that it will be easy to remove debris since it is swept within the strainer. If this orientation is required, ensure that the strainer is reinforced to ensure its mechanical stability.Another option for installation is pointing the cone facing upstream:

In the photo above, debris is swept to the side of the strainer. The outside to inside flow pattern is an advantage in that any plugging of the strainer will start in the outside and work it’s way in.