Sintered Metal Sparger

On the other hand, Spargers are an industry tool designed to deliver gas into bioreactors, fermentation tanks, and other flotation cells. Also, it ensures the bubbles are dispersed evenly throughout the cell’s liquids.

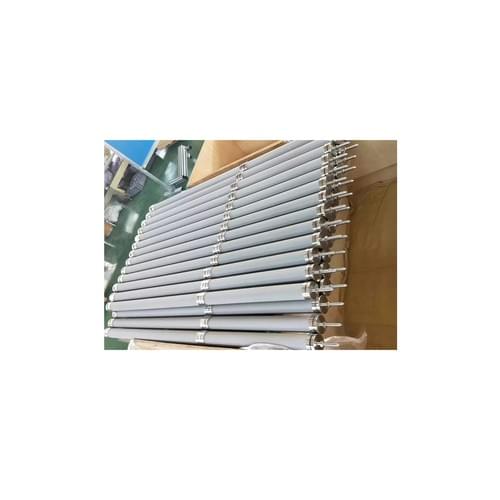

It is a porous tube with fine holesthat ensures the perfect distribution of gases in liquids by thousands of tiny bubbles.

It is positioned below the surface of the tank.

Sintered metal is a solid product that is made by applying the process of powder metallurgy. Here, different types of metals and alloys (bronze, nickel, stainless steel, brass, and titanium) are used.

On the other hand, Spargers are an industry tool designed to deliver gas into bioreactors, fermentation tanks, and other flotation cells. Also, it ensures the bubbles are dispersed evenly throughout the cell’s liquids.

- It is a porous tube with fine holesthat ensures the perfect distribution of gases in liquids by thousands of tiny bubbles.

- It is positioned below the surface of the tank.

Metal Sintering Process

The sparger elements or tubes are produced by using sintered metal powder. The powder metallurgy or metal sintering process is all about blending fine powder materials and pressing these powders to get the desired shape. After achieving the desired shape, the compressed part is heated in a controlled vacuum.

However, the process is divided into three main steps:

Selection of powder

According to the technical parameters provided by customers, STD conducts professional analysis from the aspects of metal powder material, particle size and bulk density, and selects and recommends suitable metal film materials.

Compaction

Compress the metal powder into the desired shape. This is usually done with a die or mold under isostatic cool pressing. In order to achieve the desired shape, the metal powder is placed under high pressure. Some of the most common shapes for sinter metal filter elements include disks, rings, and cylinders.

Sintering

The sintered process is an essential part of achieving the required mechanical properties. A vacuum sintering furnace performs a heat treatment process by maintaining a controlled temperature. The heating time depends on the final part application, materials (that are used), and physical requirements.

Note that in this step, the properties can be adjusted by controlling the cooling rate.

Why Sintered Spargers?

Sintered spargers are manufactured by sintering powdered metals to serve a long-lasting operation time and can operate under high temperatures. Let’s understand the key factors below:

- The sintered metal spargers produce 1 mm tiny bubbles than a drilled hole sparger.

- It helps to increase the mass transfer rate of the reactions in a bioreactor.

- Serve 5 micronsto 80 microns without welding or seams on the body.

- Rust-free and durable at high pressure.

The Common Types of Sintered Metal Sparger

In the marketplace, there are mainly three types of spargers available. Let’s scroll down to learn more about their working fields and uses.

Porous Sparger

The sparger is made of sintered metal and used in lab scale-non agitated vessels. It helps to form bubbles 10-100 times larger than the pore size. However, there is a pressure drop across the sparger, and the holes can be blocked by growth. And that is the limitation of porous sparger.

Orifice Sparger

It is a perforated pipe that is used in the small stirred fermenters and placed below the impeller in the form of crosses or rings. The air holes are drilled under the surfaces of the holes, and their diameter is at least 6mm. In some cases, the sparger is used in yeast manufacture, effluent treatment, and production of SCP. The ideal size of the orifice is ~ ¾ of the impeller diameter.

Nozzle Sparger

It is a single open/partially closed pipe that is positioned below the impeller and used on a large scale. When air is passed through the nozzle sparger, there is lower pressure loss, which won’t get blocked. It is mostly used in the laboratory and industrial scale fermenter.

Another type of Sparger is Combined Sparger Agitator. The type is not as popular as others. Let’s check out below what it is.

Combined Sparger-agitator

This sparger is responsible for supplying air via the hallow agitator shaft and emitting air through the holes in the disc or blades of the agitator.

How Does Sintered Metal Sparger Work?

Earlier sparging only worked to discharge gas and included slurry backflow protection. But now, sparger technology usage is vast.

Sintered metal spargers are temperature and corrosion resistant. Generally, spargers have an area that is the connection point for gas & liquid. Sparger’s release even and consistent amounts of gas. The sparging process with higher efficiency gets finds bubble propagation.

When the sparger releases the gas, the generated bubbles encounter the liquid, and gas in smaller bubbles tends to be absorbed fast by the liquid. When several bubbles get merged, they form a large bubble making the surface lost.

The Most Common Features of Sintered Metal Sparger

As we all know, traditional bio-fermentation technology adds extra value in the field of innovation, because it allows higher gas absorption than standard by lowering energy costs. Higher or faster absorption helps to increase cycle times by saving time.

However, you may already get some idea about its features. For more detailed information, scroll down:

Rugged and Durable

The sintered metal sparger ensures trouble-free operation over many years with its full welded structure design and high structural integrity.

High Flow Rate

The sparger is made of the metal material sintering process, which can easily deal with a high tensile strength that is suitable for high flow rates and high-pressure applications.

Outstanding Aeration

The sparger comes with good permeability and pore size is wear-proof and has controllable porosity.

Uniform Porosity

The sparger offers different pore diameters so that you can control the size of bubbles as per the specific application.

Heat Resistance

High temperature and pressure resistance, up to 900℃

Corrosion Resistance

Help to increase the surface area almost 8-10 times than a drilled pipe sparger that ensures 100% seamless construction.

Structural Elements

In catalyst reaction, offer good mechanical properties, including shape stability, self-supporting elements, and support grid.

Uses

Filtration, washing, and drying in the pharmaceutical industry.