Pre-Packed Well Screen

Pre-Packed Well Screen for Stand-Alone Applications

The pre-packed well screen is designed to provide exceptional sand control in oil, gas, and water wells, thanks to its innovative construction. As a modification of the traditional pipe-based wire-wrapped screen, the pre-packed screen incorporates a modular gravel pack, making it particularly effective for sand control in scenarios where conventional gravel packing may not suffice.

Features

1. Versatile Applications: Ideal for oil and gas well completions, especially in open or cased holes with unconsolidated formations where a stand-alone screen is required. Its unique design allows for easy installation, streamlining the drilling process.

2. Corrosion Resistance: Constructed from stainless steel, the pre-packed screen is highly resistant to erosion, ensuring durability and longevity in harsh environments.

3. Integrated Gravel Pack: The pre-packed screen features an internal packed layer, eliminating the need for separate gravel placement. This configuration significantly reduces drilling time and enhances operational efficiency.

4. Robust Construction With reinforced support rods, the pre-packed screen boasts a strong structure that minimizes maintenance costs and enhances reliability over time.

5. Cost-Effective Solution: Compared to slotted liners, the pre-packed screen offers a more affordable option for sand control, delivering excellent performance without compromising on quality.

Overall, the pre-packed well screen is a reliable and efficient choice for sand control in various well applications, combining innovative design with practical benefits to optimize well performance.

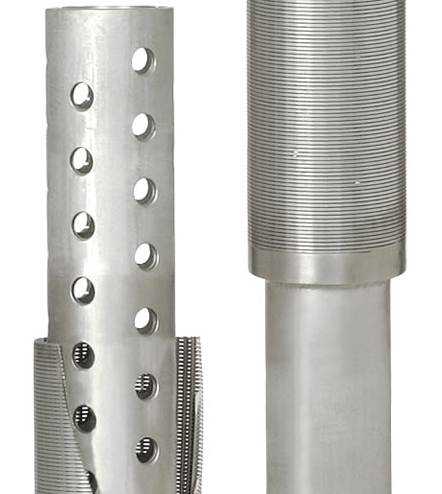

Pre-Packed Well Screen: Vertical and Side View Overview

Construction

The pre-packed well screen consists of six key components arranged from the outermost to innermost layers:

1. Outer Screen: The first line of defense, providing structural integrity and filtration.

2. Outer Support Rod: Reinforces the outer screen and adds stability to the overall structure.

3. Pre-Packed Gravel: An annular space between the outer and inner screens filled with silica sand of specific sizes, coated with resin or ceramic beads for enhanced performance.

4. Inner Screen: A secondary layer that further filters the incoming fluid, providing additional protection against sand ingress.

5. Inner Support Rods: These provide extra support to the inner screen, ensuring durability and effective sand control.

6. Base Pipe: The foundational component that houses the inner screen and supports the overall structure.

This typical model features dual wire-wrapped screens, where the perforated base pipe is enveloped by an inner wire-wrapped jacket. The diameter of this inner jacket is smaller than that of the outer jacket, creating a void that is filled with precisely sized sand, enhancing the screen's effectiveness.

Materials

Pre-packed screens can be manufactured using various materials to suit specific applications, including:

- Stainless Steel 304 and 316L: Known for their excellent corrosion resistance and durability, these materials are ideal for challenging environments.

- Low Carbon Steel: A cost-effective option that offers good mechanical properties.

- Special Alloys (e.g., Model 400)**: Available upon request for specialized applications requiring specific material properties.

The choice of materials and the gauge of the wire jacket are determined by the packed sand specifications, while the sand size is tailored based on the required particle size distribution for optimal performance. This robust design ensures that the pre-packed well screen is highly effective for sand control in various well applications.

Customization for Pre-Packed Screens

A pre-packed screen must be tailored to meet the specific requirements of each application to ensure optimal performance. While some general data is available, there are critical specifications that need to be provided by our customers to enhance the effectiveness of the screen.

Key Specifications Required

1. Slot Width: The width of the slots directly influences the screen's filtration capacity. This measurement must be customized based on the particle sizes expected in the formation.

2. Formation Diameter: Understanding the diameter of the formation is essential for designing a screen that fits correctly and functions effectively in its environment.

3. Open Area: The percentage of open area in the screen impacts flow rates and overall efficiency. It is crucial to determine this based on the anticipated flow requirements and well conditions.

4. Additional Data: Other factors such as operating pressure, temperature, and the chemical composition of the fluids being processed can also significantly affect the screen's performance and should be communicated to ensure the design meets all operational demands.

By gathering this vital information, we can manufacture a pre-packed screen that is specifically designed for the unique conditions of the well, maximizing its efficiency and effectiveness in sand control and filtration processes. This collaborative approach ensures that each pre-packed screen performs optimally under the specified operational parameters.